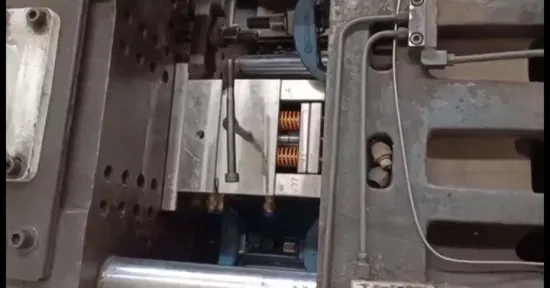

Hot Runner Flip Top Cap Mould with Cap Closing System in

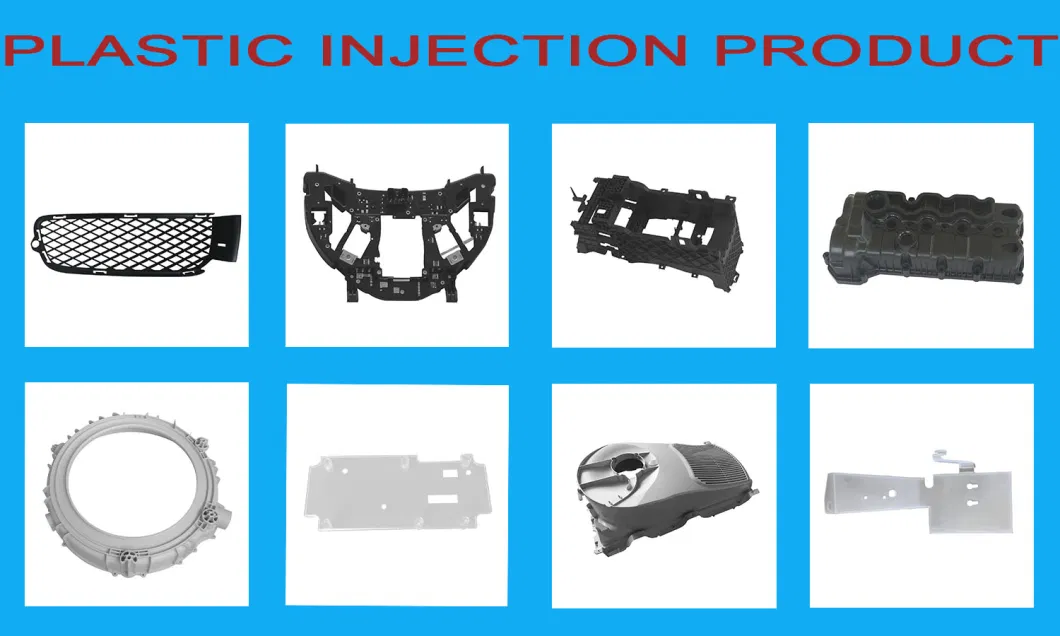

Specialize in plastic Injection Mold/Hot Runner Mold/Gas Assistant Mold/High Glossy Mold/2K Injection Mold/Over Mold/IML;

Basic Info.

| Model NO. | S03-252 |

| Application | Car, Household Appliances, Furniture, Electronic |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| Lead Time | 20-30 Days |

| Mould Base | Yudo |

| Cavity | 1X4 |

| Core Steel | P20 |

| Transport Package | Wooden Box |

| Specification | CE/SGS/RoSH |

| Trademark | RootChina |

| Origin | Qingdao Shandong |

| HS Code | 8480710090 |

| Production Capacity | 360 Sets/Year |

Product Description

Specialize in plastic Injection Mold/Hot Runner Mold/Gas Assistant Mold/High Glossy Mold/2K Injection Mold/Over Mold/IML/Stack Mold.Professional Auto Engine Part Mould Manufacturer over 14 years, certificated by ISO 9001: 2008.

Offered Service:

1.Mold progress report and tooling schedule will be provided weekly.2.The first testing sample for buyer's inspection and work out improvement requirements will be provided.3.Mold testing video, 2D part drawing and 3D mold design before shipment will be provided.

Specification:

Item: Plastic Injection MoldPart Material: PC/PP/PBT/ABS/PMMA/PU/PE/PVCCore &Cavity Steel: P20/H13//GS2344/NAK80/ASSAB718HASSAB8407Mold Base Steel: P20/1050/S50C/Runner: Hot or ColdGate Type: Sprue Gate/Pin Point Gate/Edge Gate/Submarine Gate/Fan Gate/Ring GateCavity No: Single or Multiple.Mold Base Standard: DME/LKM/HASCO/Etc.Spare Parts Standard: DME/HASCO/DAIDO/MISUMI/Customized is acceptable.Mold Life: 30k-1, 000 kCycle Time: 10-120 sLead Time: 30-45 daysInjection Machine: 50-1200 Ton

Payment and DeliveryPayment: TT 50% in advance, Balance before shipmentDelivery Time: 30-45 days

| Specification | |

| Design Software: | UG/CAD |

| Analysis Software: | Moldflow |

| Preferred Formats: | STP/IGES/UG |

| Design Time: | 7-15 days |

| Manufacture Time: | 20-30 days |

| Delivery Time: | 30-45 days |

A: When the mold for your custom enclosure is cut, we put it on one of our molding machines and make a few sample parts to send you for your approval. When you approve the sample parts we can move to the production phase of the process

Q:How do we know about the deliery status?

A: We will immediately inform you the tracking number once we get it from shipping agent. Besides, we will update the latest shipping information

Q: What is your quotation element?

A: Product structure, material, size, craftsmanship, weight, quality, order and other informationQ: How can we guarantee quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment

Q: Can you make casting according to our drawing?

A: Yes, we can make casting according to your drawing, 2D drawing, or 3D CAD model. It would be better if 3D CAD model can be shared, so that we can design mold more efficient.

You may also like

Send inquiry

Send now