Custom

Basic Info.

| Model NO. | AIL-M-0093 |

| Application | Commodity |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | Lkm |

| Customized | Customized |

| After-sales Service | 3 Years |

| Transport Package | OPP Bag |

| Specification | 150*100*100mm |

| Origin | Dongguan |

| HS Code | 8480719090 |

Product Description

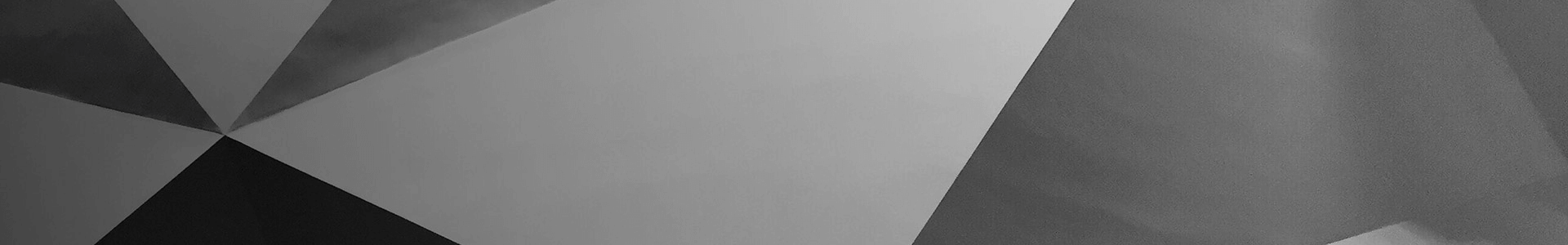

Custom-made semi-transparent plastic PP cap injection molding Detailed Photos General information & policy for our OEM/ODM plastic injection Mold:| Detailed info for Mould steel | ||

| Mould material | Hardness | Mould life |

| P20 | HRC 28-33 | >300,000 shots |

| 718 | HRC 33-36 | >500,000 shots |

| H13 | HRC >43 | >800,000 shots |

| 2344 | HRC >48 | >800,000 shots |

| S136 | HRC 48-52 | >1,000,000 shots |

Lead Time :

| Quantity(Sets): | 1 - 1 | >1 |

| Est. Time(day): | 30~45 | To be negotiated |

| Description of Ambition Plastic Injection Moulds: | |

| Mold material: | 45#, P20, 718, 2738, NAK80, S136, H13, 1.2344 etc. |

| Mold base: | LKM, HASCO, etc. |

| Standard Component: | DME, HASCO, JIS, etc. |

| Cavity: | Single/Multi |

| Runner: | Hot/Cold |

| Mold life: | 10,0000~5,000,000shots |

| Design software: | UG, PROE, CAD, SolidWorks, etc. |

| Plastic material: | PP, PC, PE, PS, PU, ABS, PVC, PA, POM, PMMA, PET, PPR, etc. |

| Delivery time: | 40--60days |

| Package: | Wooden Case |

| Delivery: | By Sea |

| Specifications: | Depends on the customer's requirements |

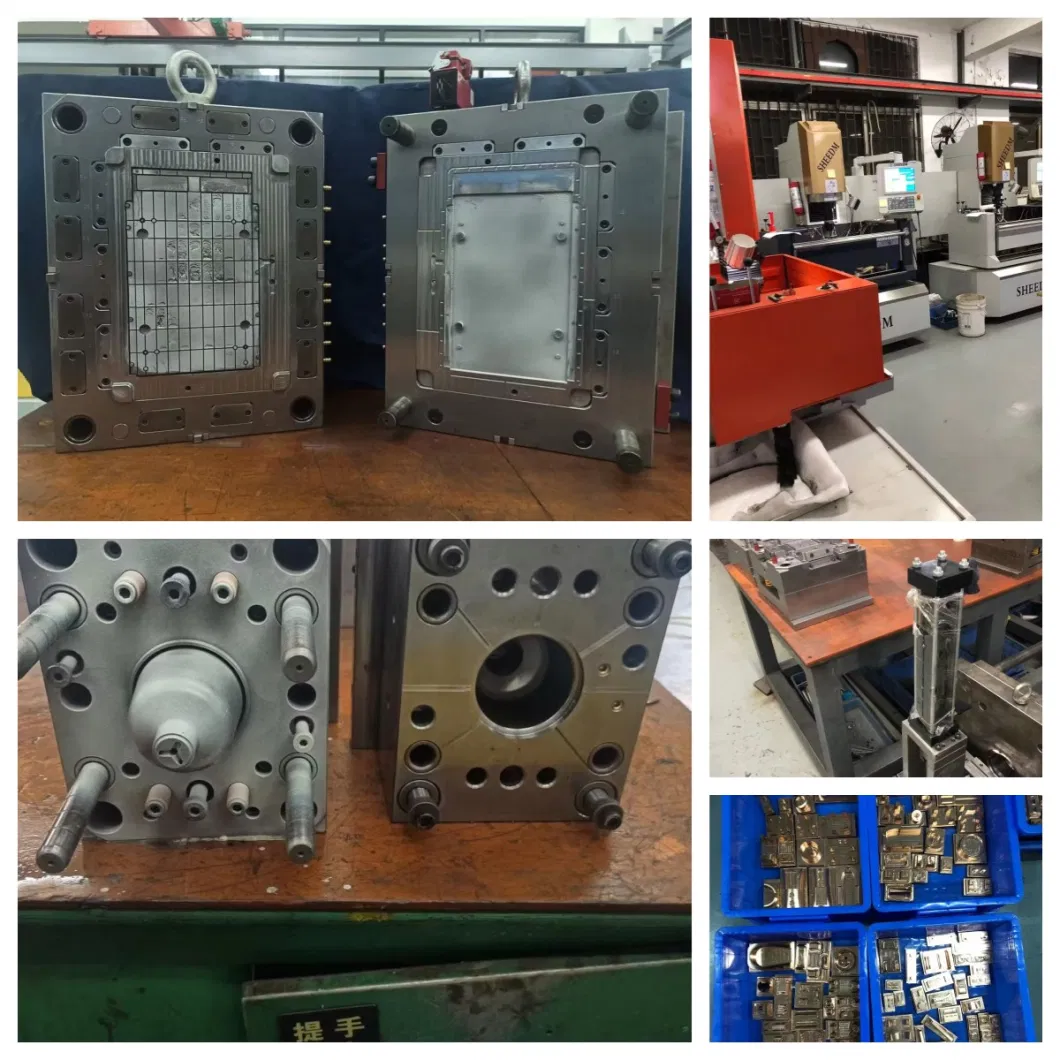

| Process Machine: | CNC, High-Speed Carver, EDM, Wire Cut, Driller, Grinder, fly cutter, etc. |

Ambition Mould Trade Process:

| 1. Quote | According to the sample, drawing, and specific requirements. |

| 2. Discussion | Mold material, cavity number, price, runner, payment, etc. |

| 3. S/C Signature | Approval for all the items |

| 4. Advance | Pay 50% by T/T |

| 5. Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mold, we will send the customer the report. |

| 6. Mould Design | We make mold design on the basis of confirmed product designs and send them to the customer for confirmation. |

| 7. Mold Tooling | We start to make mold after the mold design confirmed |

| 8. Mold Processing | Send report to customer once each week |

| 9. Mold Testing | Send trial samples and try-out reports to the customer for confirmation |

| 10. Mold Modification | According to the customer's feedback |

| 11. Balance Settlement | 50% by T/T after the customer approves the trial sample and mold quality. |

| 12. Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Company information:

Founded in 2010, We are dedicated to providing our customers with the highest level of plastic mold manufacturing & injection molding services. We always insist on the concept of customer satisfaction and qualities. We have set some examples of customers in different countries for new customer referrals. We really hope that we can build a long-term business relationship with win-win cooperation with you.We can make all kinds of plastic injection molds including automotive part molds, cosmetic part molds, medical part molds, home appliance molds, electronic part molds, and so on.We have rich experience in making customized plastic injection mold. Send me the inquiry with the drawing and requirement (steel raw material, cavity no. etc) for mold, and I will reply to you within 24 hours and quote for you within 2 working days.

Why Choose Us:

| Best design, competitive price |

| Over 10 years' Rich experience in this field |

| Professional in design & making plastic mold |

| One stop solution |

| On-time delivery |

| Best after-sale service |

| Specialized in all kinds of plastic injection molds |

Packaging & Shipping: FAQ:

1. Q: I have an idea for a new product, but I don't know if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling, and likely set-up costs.

2. Q: What are the advantages of having my parts manufactured locally?

A: We can offer quick reaction times to any changes in specification, batch size, or material. We can ship small or large quantities anywhere in North America, and Europe overnight to accommodate unforeseen changes in demand.

3. Q: My components have already been developed in CAD. Can you use the drawings?

A: Yes! DWG, DXF, IGES, Solid works and STP, X_T files can all be used to generate quotes, models, and mold tools - this can save time and money in producing your parts.

4. Q: Can I test my idea/component before committing to mold tool manufacture?

A: Yes, we can use CAD drawings to make Prototype models for design and functional evaluations or market tests.

5. Q: What type of plastic is best for my design/component?

A: Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

6. Q: What type of mold tool do I need?

A: Mould tools can be either a single cavity (one part at a time) or multi-cavity (2,4, 8, or 16 parts at a time). Single-cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend the best tooling option for you.

7. Q: Ok, I've decided to go ahead with my project. How long will it take to get my parts?

A: It can take 3 to 6 weeks to have the mold tool manufactured depending on the part's complexity, size, and the number of impressions/ cavities (single or multiple). After we receive your final approval on the tool's preliminary design, you can expect delivery of T1 parts within 3-6 weeks. And during the mold building process, mold builds Weekly Update will be provided to you every week for your better understanding of the manufacturing progress in our workshop.